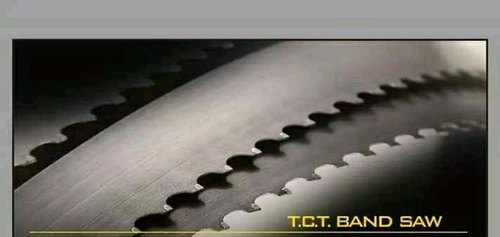

Carbide Tips Bandsaw Blade

Price 430 INR/ Foot

MOQ : 15 Feet

Carbide Tips Bandsaw Blade Specification

- Tool Type

- Carbide Tips Bandsaw Blade

- Hardness

- Carbide tipped; extremely high hardness for durability

- Cutting Force

- High - suitable for hard metals and alloys

- Cutting Capacity

- Capable of cutting hardwood, metals, and alloys

- Material

- High Carbon Steel with Carbide Tips

- Cutting Speed

- Designed for high-speed cutting operations

- Coating Type

- Uncoated

- Operate Method

- Machine driven

- Drill Bits Types

- Not applicable for bandsaw blades

- Length

- Variable customized per requirement

- Shape

- Rectangular blade with teeth along one edge

- Cutter Type

- Bandsaw blade with carbide-tipped teeth

- Features

- Wear-resistant, durable, long tool life

- Cutting Accuracy

- High precision

- Machine Type

- Bandsaw machine

- Operation Type

- Manual or automated machine compatible

- Diameter

- Not applicable to this blade type

- Processing Type

- Industrial fabrication, metal cutting

Carbide Tips Bandsaw Blade Trade Information

- Minimum Order Quantity

- 15 Feet

- FOB Port

- Ex. Factory

- Payment Terms

- Cash on Delivery (COD), Letter of Credit at Sight (Sight L/C), Cheque

- Supply Ability

- 50 Feet Per Month

- Delivery Time

- 3 Days

- Packaging Details

- Corrugated Box

- Main Export Market(s)

- Australia, Central America, South America, Western Europe, Middle East, Asia, Eastern Europe, North America, Africa

- Main Domestic Market

- All India

About Carbide Tips Bandsaw Blade

| Material | Stainless Steel |

| Brand | OMKAR |

| Usage/Application | TIMBER |

| Size/Dimension | 63mm to 76mm |

| Shape | Round |

| Finishing | Sandblasted |

| Pitch | 12 TPF / 14 TPF/ 16 TPF |

Carbide Tips Bandsaw Blade

Additional Information:

- Delivery Time: 3 days

- Packaging Details: corrugated box

Precision Cutting for Multiple Materials

Designed to handle wood, plastics, and an array of metals, the Carbide Tips Bandsaw Blade stands out for its cutting efficiency. The carbide tips provide exceptional hardness, allowing for the smooth and accurate processing of even the toughest materials, while the customizable TPI and tooth types make this blade adaptable to various industrial needs.

Dependable Construction for Longevity

Manufactured from high-carbon steel with robust carbide tips, this blade resists wear and heat, maintaining its cutting edge even during prolonged use. Its precision-ground finish delivers consistent results, reducing downtime and wastage. Meeting recognized international standards, the blade combines reliability with safety for any industrial setup.

Versatility and Customization

This bandsaw blade can be tailored in both length and tooth configuration to fit specific machinery and project requirements. Whether in a manual or automated system, the blades compatibility and high-speed performance ensure smooth operations for manufacturers, suppliers, and traders across industries.

FAQs of Carbide Tips Bandsaw Blade:

Q: How do I select the right teeth per inch (TPI) and tooth type for my application?

A: Choose a lower TPI and hook tooth type for fast, coarse cuts in wood or softer metals, and a higher TPI with regular or skip teeth for fine, precision cutting in harder materials. The carbide tips ensure durability, regardless of the chosen configuration.Q: What materials can the Carbide Tips Bandsaw Blade cut effectively?

A: This blade is suitable for hardwood, plastics, ferrous metals like steel, non-ferrous metals such as aluminum and copper, and tough alloys. Its carbide-tipped teeth make it ideal for both soft and hard materials.Q: When should I consider using a carbide-tipped bandsaw blade over standard steel blades?

A: Opt for a carbide-tipped blade when you require longer tool life, higher durability, and the ability to cut hard or abrasive materials at higher speeds. Carbide tips maintain sharpness and resist wear better under intensive industrial use.Q: Where can I source these bandsaw blades in custom sizes?

A: Custom-sized Carbide Tips Bandsaw Blades are available through distributors, exporters, importers, manufacturers, and suppliers in India. Specify your required length and tooth configuration when ordering.Q: What is the process for installing and maintaining these bandsaw blades?

A: Installation involves mounting the blade correctly on the bandsaw machine, ensuring proper tension and alignment. Regular cleaning, inspection for wear, and prompt replacement extend blade life and ensure cutting accuracy.Q: What are the key benefits of using a Carbide Tips Bandsaw Blade in industrial fabrication?

A: The key benefits include high cutting precision, capability to withstand high speeds and temperatures, extended tool life, reduced downtime for blade changes, and compatibility with both manual and automated bandsaw machines.Q: Is there any specific operating method or machine required for these blades?

A: These blades are designed for compatibility with a wide range of bandsaw machines, whether operated manually or through automated systems, making them suitable for diverse industrial environments.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Bandsaw Blade and Tools Category

Band Saw Blade

Price 105 INR / Roll

Minimum Order Quantity : 1 Foot

Material : Others, High Speed Steel (HSS)

Usage : Industrial

Color : Silver

Hardness : High Hardness

TCT Band Saw Blade

Price 430 INR / Piece

Minimum Order Quantity : 1 Foot

Material : High Speed Steel

Usage : Industrial

Color : Grey

Send Inquiry

Send Inquiry