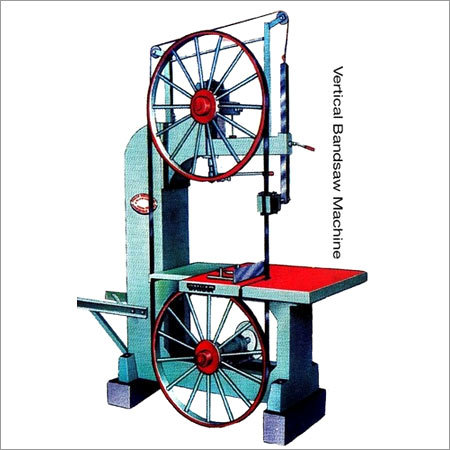

Vertical Bandsaw Machine OVB-24

Price 88000 INR/ Unit

Vertical Bandsaw Machine OVB-24 Specification

- Drive Motor

- 2 HP

- Product Type

- Metal Cutting Bandsaw

- General Use

- For straight, irregular, and contour cutting of steel and non-ferrous materials

- Material

- Cast Iron, Steel

- Type

- Vertical Bandsaw Machine

- Capacity

- 9 (inches)

- Weight (kg)

- 850 kg

- Computerized

- No

- Automatic

- No

- Cutting Speed

- 20 100 m/min (Variable)

- Cutting Thickness

- Up to 300 mm

- Cutting Function

- Vertical cutting, contour, and curve cutting

- Cooling System

- Integrated coolant pump

- Drive Type

- Belt Drive

- Voltage

- 415V, 3 Phase, 50 Hz

- Dimension (L*W*H)

- 1100 x 760 x 1700 mm

- Feature

- Heavy-duty frame, precision guide system, tilting table

- Color

- Green

- Motor

- 2 HP Electric Motor

- Mechanical Precision

- High accuracy with ball bearing guides

- Software Detail

- N/A (Manual Operation)

- Cutting Method

- Band Saw Blade

- Control System

- Manual

- Cutting Material

- Steel, Copper, Brass, Aluminum, Non-ferrous Metals

- Cutting Area

- 600 x 400 mm

Vertical Bandsaw Machine OVB-24 Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Ex. Factory

- Payment Terms

- Cash on Delivery (COD), Letter of Credit at Sight (Sight L/C), Cheque

- Supply Ability

- 20 Units Per Month

- Delivery Time

- 1 Days

- Sample Available

- Yes

- Packaging Details

- Wooden Box

- Main Export Market(s)

- Asia, Australia, Central America, North America, Western Europe, Middle East, South America, Eastern Europe, Africa

- Main Domestic Market

- All India

About Vertical Bandsaw Machine OVB-24

Vertical Bandsaw Machine OVB-24

Specification

|

Dia of Saw Wheel |

24 inch |

|

Max Cutting Height |

18 inch |

|

Speed of Saw Wheel |

600 RPM |

|

Country of Origin |

Made in India |

|

Capacity |

450 mm (Cutting) |

|

Brand |

Omkar |

|

Material |

Mild Steel |

|

Model Name/Number |

OVB-24 |

|

Motor Power |

5 HP |

|

Usage/Application |

Wood Cutting |

|

Size/Dimension |

24x24 ft (Table) |

Exceptional Cutting Versatility

Capable of cutting steel, copper, brass, aluminum, and non-ferrous metals, the OVB-24 delivers high-precision straight, contour, and irregular cuts. The 600 x 500 mm tilting table and variable speed drive allow users to handle a wide array of materials and shapes with accuracy and consistency.

Robust Construction and Safety

Built with a heavy-duty cast iron and steel frame, the OVB-24 ensures durability and stability in demanding industrial environments. The low noise levels, powder-coated surface finish, blade guard, and integrated coolant system collectively create a safer, cleaner, and longer-lasting workspace.

User-Friendly Operation and Maintenance

The manual feed mechanism and manual blade tension with a calibrated spring make the OVB-24 straightforward to operate for skilled or semi-skilled users. Easily accessible replacement parts and a recirculating coolant system minimize downtime and simplify maintenance routines.

FAQs of Vertical Bandsaw Machine OVB-24:

Q: How do you operate the OVB-24 Vertical Bandsaw Machine for various cuts?

A: To use the OVB-24, adjust the table tilt (045) and set the blade tension with the calibrated spring. Using the ball bearing guided blade and manual feed, position the workpiece on the 600 x 500 mm table and guide it to achieve straight, curve, or contour cuts, adjusting the cutting speed (20100 m/min) as needed.Q: What are the main benefits of the tilting table and ball bearing blade guide system?

A: The tilting table (045) increases flexibility, making bevel and angled cuts possible. The ball bearing blade guide ensures stable, vibration-free operation, enhancing mechanical precision and extending blade life.Q: When should the coolant system be used during cutting operations?

A: For all cutting tasks, especially with metals, the integrated coolant recirculating pump should be engaged. This reduces heat buildup, prolonging blade life and ensuring smoother, cleaner cuts.Q: Where is the OVB-24 most commonly installed and used?

A: The OVB-24 is designed for floor mounting in engineering workshops, fabrication units, and sheet metal cutting setups, making it suitable for professional industrial applications.Q: What replacement parts are available and how quickly can they be obtained?

A: Replacement parts for the OVB-24, including blades, guides, and tensioning components, are readily available through authorized distributors, suppliers, and service centers, ensuring minimal downtime.Q: How does the OVB-24s manual operation affect its usage and required skill level?

A: The machines manual control system makes it intuitive for skilled or semi-skilled operators. Manual blade feed and tensioning offer precise control, though operator attentiveness and experience ensure optimal cutting results.Q: What are the primary applications and materials suited for the OVB-24 Vertical Bandsaw Machine?

A: The OVB-24 excels in cutting steel, copper, brass, aluminum, and non-ferrous metals, handling tasks such as contour, straight, and irregular cutting in general engineering, sheet metal, and fabrication environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bandsaw Machine Category

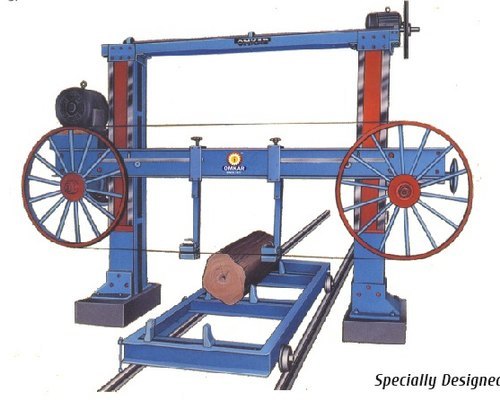

Vertical Bandsaw Machine 42"

Price 170000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : No

Product Type : Woodworking Equipment

Automatic : No

Color : as par requirment

Horizontal Band Saw Machine 42

Price 275000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : No

Product Type : Horizontal Metal Cutting Band Saw

Automatic : No

Mini Horizontal Bandsaw Machine

Price 307000 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : No

Product Type : Cutting Machine

Automatic : Yes

Color : White

Portable Band Saw Machine

Price 380000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Woodworking Machine

Send Inquiry

Send Inquiry