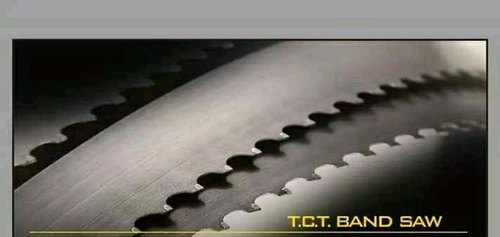

TCT Band Saw Blade

Price 430.0 INR/ Foot

TCT Band Saw Blade Specification

- Hardness

- Very hard

- Usage

- Industrial

- Material

- High Speed Steel

- Size

- Standard

- Product Type

- Band Saw Blade

- Color

- Silver

TCT Band Saw Blade Trade Information

- Minimum Order Quantity

- 1 Foot

- Supply Ability

- 100 Feet Per Month

- Delivery Time

- 3 Days

- Sample Policy

- Contact us for information regarding our sample policy

- Main Domestic Market

- All India

About TCT Band Saw Blade

Established in the year 1977, we have been engrossed in manufacturing, exporting and supplying a wide range of TCT Band Saw Blade. This blade is manufactured using quality examined raw material by our ingenious professionals at our advanced production set up. The offered blade is used for cutting wood and other materials in hassle free manner. Additionally, the provided TCT Band Saw Blade can be bought from us at economical rates.

Key Points:

- Sturdiness

- Fine finish

- Longer life

- Non corrosive

Exceptional Durability and Precision

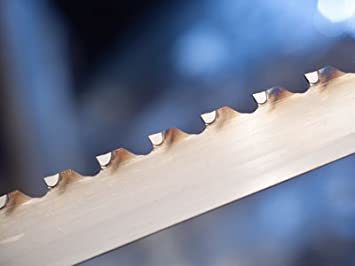

With a very hard high-speed steel composition and robust carbide tips, the TCT Band Saw Blade stands out in its category. Its manufacture ensures outstanding resistance to wear and deformation, even during continuous industrial use. This design leads to longer blade life and minimizes downtime for replacements, thus streamlining operations for businesses.

Versatile Industrial Applications

Designed specifically for industrial environments, this band saw blade handles a wide range of materials, from metals to hard woods. Its adaptability is favored by distributors and manufacturers across diverse industries. The blades standard size ensures compatibility with most band saw machines used in Indias industrial sectors, providing flexibility for various cutting tasks.

FAQs of TCT Band Saw Blade:

Q: How does the TCT Band Saw Blade enhance industrial cutting processes?

A: The TCT Band Saw Blade utilizes high speed steel with carbide tips, making it extremely hard and wear-resistant. This significantly improves cutting efficiency, achieving cleaner cuts and reducing blade change frequency, which benefits high-volume industrial operations.Q: What materials can be efficiently processed with this band saw blade?

A: Thanks to its hardness and robust construction, this blade is ideal for cutting tough metals, hardwoods, and composite materials, making it suitable for a wide variety of industrial processes.Q: When should I replace a TCT Band Saw Blade for optimal performance?

A: Replacement is recommended when you notice decreased cutting precision, slower feed rates, or visible signs of wear on the blade teeth. Timely replacement ensures continuous high-quality results and prevents potential machine damage.Q: Where can I source the TCT Band Saw Blade in India?

A: The blade is widely available through leading distributors, exporters, importers, manufacturers, suppliers, and traders across India. You can get it from industrial supply stores or directly from manufacturers.Q: What is the manufacturing process for high-speed steel TCT band saw blades?

A: The process involves forming high-speed steel into blades, then brazing tungsten carbide tips onto the teeth. These tips are precisely ground to ensure sharpness, providing the blade with exceptional hardness and lifespan.Q: How should the TCT Band Saw Blade be used for maximum benefit and safety?

A: Use the blade at recommended speeds and material feed rates, ensuring proper tension and alignment on the saw. Regular maintenance, such as cleaning and inspection, preserves performance and extends blade life.Q: What are the primary advantages of choosing this blade for industrial applications?

A: Its very hard composition ensures prolonged cutting performance, reduced maintenance costs, and increased productivity. The compatibility with standard machines and superior cutting quality make it an ideal choice for industrial users.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bandsaw Blade and Tools Category

Band Saw Blade

Price 105 INR / Roll

Minimum Order Quantity : 1 Foot

Material : Others, High Speed Steel (HSS)

Processing Type : Precision Cutting

Cutter Type : Toothed Blade

Machine Type : Band Saw Machine

Carbide Tips Bandsaw Blade

Price 430 INR / Foot

Minimum Order Quantity : 15 Feet

Material : Others, High Carbon Steel with Carbide Tips

Processing Type : Industrial fabrication, metal cutting

Cutter Type : Bandsaw blade with carbidetipped teeth

Machine Type : Bandsaw machine

Wood Cutting Band Saw Blade

Price 117 INR / Roll

Minimum Order Quantity : 1 Foot

Material : Others, High Carbon Steel

Processing Type : Wood Cutting

Cutter Type : Bandsaw Cutter

Machine Type : Bandsaw Machine

Wood Cutting Blade

Material : HighSpeed Steel (HSS), Others

Processing Type : Wood Cutting

Cutter Type : Saw Blade

Machine Type : Bandsaw

Send Inquiry

Send Inquiry