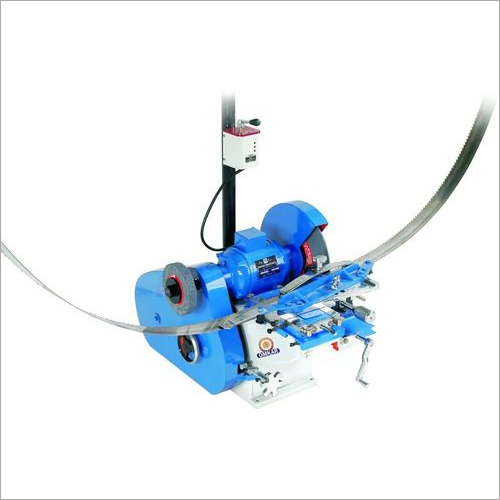

Automatic Blade Grinding Machine

Price 47500.00 INR/ Unit

Automatic Blade Grinding Machine Specification

- Product Type

- Woodworking Equipment

- Machine Type

- Other

- Machine Style

- Vertical

- Capacity

- 10-50 Blade Per Hour Milliliter (ML)

- Voltage

- 220-240 V Ohm (ohm)

- Power

- Electric

- Automation

- Semi Automatic

- Motor

- 1.5 HP Induction Motor

- Speed

- 1440 RPM m/s

- Dimension (L*W*H)

- 1200 x 900 x 1500 mm Perch

- Weight

- 350 Kg Drams (dr)

- Color

- Blue

Automatic Blade Grinding Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Ex. Factory

- Payment Terms

- Cash on Delivery (COD), Letter of Credit at Sight (Sight L/C), Cheque

- Supply Ability

- 30 Units Per Month

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Packaging Details

- wooden box packing

- Main Export Market(s)

- Central America, Asia, Australia, North America, South America, Western Europe, Middle East, Eastern Europe, Africa

- Main Domestic Market

- All India

About Automatic Blade Grinding Machine

Automatic Blade Grinding Machine

Our company offers highly robust and energy efficient Automatic Blade Grinding Machine that is used to sharpen blades for various cutting applications such as in woodworking, metalworking, and printing industries. This motor-driven machine is installed with a sturdy grinding wheel to easily sharpen the blades to achieve desired level of sharpening. It requires a standard alternating voltage of 220 to 240 volts. Automatic Blade Grinding Machine designed by our company can be delivered to our clients with a supply ability of 30 units per month at a reasonable and low price.

Specification

|

Motor Power |

1 HP |

|

Phase |

Three Phase / Single Phase |

|

Speed |

2880 RPM |

|

Grinding Wheel Size |

12" x 0.5" and our 6" x 1" |

|

Weight |

155 kg |

|

Country of Origin |

Made in India |

|

Brand |

Omkar |

|

Automation Grade |

Automatic |

|

Sharpening Speed (Tooth/min) |

90 - 95 tooth/min |

|

Type of Grinding Machine |

Sharpener |

High-Performance Blade Compatibility

Engineered for versatility, the grinding machine supports blade lengths up to 24 inches, making it suitable for a wide spectrum of industrial applications such as planers, knives, and chipper blades. Its robust construction ensures reliable performance, even during prolonged use.

Enhanced Safety and Ergonomics

The machines protective covers and emergency stop button are designed to promote operator safety at every stage of the grinding process. Manual table adjustments offer operators precise control, while noise levels remain comfortably below 70 dB for a better workplace environment.

Integrated Cooling System for Optimal Operation

With an integrated coolant tank, this grinding machine maintains optimal temperatures, extending both the tools and grinding wheels lifespan. The continuous coolant flow minimizes heat and friction, supporting consistent, high-quality results in every operation.

FAQs of Automatic Blade Grinding Machine:

Q: How is the blade grinding process performed with this machine?

A: The Automatic Blade Grinding Machine operates using a belt-driven system with an 8-inch grinding wheel and manual table adjustment. Operators secure the blade, adjust the table for precision, and utilize the integrated coolant system to keep both the blade and wheel cool during grinding.Q: What types of blades can be used with this machine?

A: This grinder is designed for knife, planer, and chipper blades up to 24 inches in length, accommodating most standard and industrial blade profiles for sharpening and maintenance.Q: When should the coolant system be used during operation?

A: The integrated coolant tank is recommended for use whenever the grinding machine is running, as it helps control the temperature, reduces friction, and prevents overheating of both the blade and the grinding wheel.Q: Where is the best place to install the grinding machine?

A: The machine is designed for floor-mounted installation in industrial workshops or facilities with proper ventilation, electrical supply, and sufficient space to operate the equipment safely and efficiently.Q: What are the safety features included with this model?

A: Key safety features include an emergency stop button for instant shutdown during emergencies as well as protective covers to shield operators from sparks, debris, and accidental contact with moving parts.Q: How does using this machine benefit blade maintenance?

A: Utilizing this grinding machine ensures blades are sharpened with precision and consistency. The integrated coolant system extends blade life, while the low noise output enhances the working environment for operators.Q: What are the power and operating requirements of the machine?

A: The machine is electrically powered and operates optimally at temperatures between 0C and 45C. Regular maintenance of the belt drive and coolant system helps maintain efficient and reliable function.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sharpener Machine Category

Automatic Teeth Setting Machine

Price 26500 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Blue

Voltage : 220 V / 380 V (Three Phase)

Machine Type : Other, Industrial Metal Working Machine

Product Type : Other, Automatic Teeth Setting Machine

Manual Bench Grinder

Price 14500 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Green

Voltage : 220240 V Milliampere (mA)

Machine Type : Other, Bench Grinder

Product Type : Other, Manual Bench Grinder

Send Inquiry

Send Inquiry