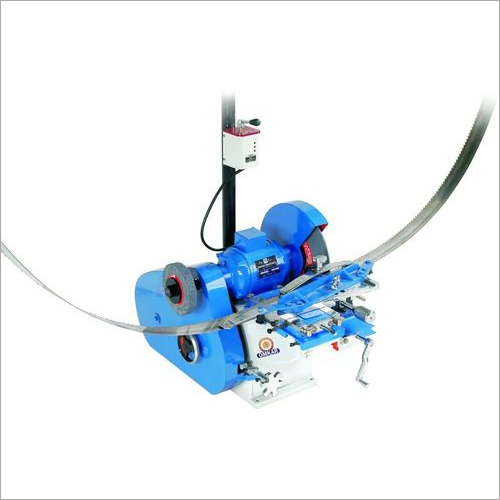

Manual Bench Grinder

Price 14500 INR/ Unit

MOQ : 1 Unit

Manual Bench Grinder Specification

- Product Type

- Manual Bench Grinder

- Machine Type

- Bench Grinder

- Machine Style

- Hand Operated

- Capacity

- 6 Inch Wheel Ltr

- Voltage

- 220-240 V Milliampere (mA)

- Power

- 375-400 Watts

- Automation

- Manual

- Motor

- Single Phase Induction Motor

- Speed

- 2850 RPM RPM

- Dimension (L*W*H)

- 360 x 210 x 250 mm Perch

- Weight

- Approx. 12 Kg Drams (dr)

- Color

- Green

Manual Bench Grinder Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Ex. Factory

- Payment Terms

- Cash on Delivery (COD), Letter of Credit at Sight (Sight L/C), Cheque

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 1 Days

- Sample Available

- Yes

- Packaging Details

- Loos Packaging

- Main Export Market(s)

- Central America, South America, Western Europe, Middle East, Eastern Europe, Asia, North America, Australia, Africa

- Main Domestic Market

- All India

About Manual Bench Grinder

Manual Bench Grinder

Specification

|

Frequency |

50 Hz |

|

Country of Origin |

Made in India |

|

Phase |

Single Phase |

|

Voltage |

240 V |

|

Material |

Mild Steel |

|

Brand |

Omkar |

|

No Load Speed |

2800 RPM |

|

Disc Diameters |

12 inch |

Precision Sharpening and Metalwork

Engineered for consistent sharpening and metal shaping, this manual bench grinder delivers precise results. Its rugged cast iron housing and stable bench-mount design ensure durability and safety even during prolonged operations. The 150 mm grinding wheel and powerful 375-400 watt induction motor combine to handle various metalworking tasks efficiently.

User-Friendly and Safe Operation

With features like a toggle ON/OFF switch, eye shield, and a tool rest, this grinder prioritizes operator safety and user comfort. The air-cooling system keeps the device running optimally, while the low noise level promotes a more comfortable working environment in workshops and industrial settings.

FAQs of Manual Bench Grinder:

Q: How do I safely operate the manual bench grinder?

A: To safely operate the grinder, secure it to a stable bench using the mounting fittings. Always use the eye shield and tool rest, ensure the toggle switch is off before plugging in, and keep hands clear of the spinning wheel while sharpening or grinding metal.Q: What materials can this bench grinder effectively handle?

A: This bench grinder is designed for sharpening, grinding, and shaping a variety of metals. Its robust construction and high-speed motor make it suitable for most ferrous and some non-ferrous metals commonly found in workshop settings.Q: When should I use the tool rest and eye shield?

A: The tool rest and eye shield should be used at all times while operating the grinder. The tool rest stabilizes your workpiece, and the eye shield protects you from flying debris and sparks during the grinding process.Q: Where is this bench grinder typically installed?

A: This grinder is bench-mounted, ideal for installation on sturdy workbenches in workshops, industrial facilities, or professional metalworking environments, providing a stable and safe platform for various tasks.Q: What is the process to change the grinding wheel?

A: Ensure the machine is unplugged and switched off. Remove the safety shield, loosen the arbor nut, carefully remove the worn wheel, and fit the new 150 mm x 20 mm wheel with the proper bore size (12.7 mm). Replace the shield and tighten all fittings securely.Q: What are the benefits of the manual (hand-operated) style?

A: The manual operation gives users enhanced control over grinding tasks, allowing for precision shaping and sharpening. This ensures adaptability for different workpieces, especially for detailed metalworking jobs.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Sharpener Machine Category

Automatic Blade Grinding Machine

Price 47500.00 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Blue

Machine Type : Other

Capacity : 1050 Blade Per Hour Milliliter (ML)

Speed : 1440 RPM m/s

Automatic Teeth Setting Machine

Price 26500 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Blue

Machine Type : Other, Industrial Metal Working Machine

Capacity : 5001200 pieces/hour

Speed : Variable, up to 1440 RPM

Send Inquiry

Send Inquiry